What is House wrap?

Housewrap is sheathing installed on exterior walls before the siding or other cladding is attached. The term refers to all materials (made today, typically, from plastic or spun-fiber polyethylene) designed to replace tar paper, which serves the same function. Since almost any exterior finishing material will allow at least some water to penetrate it, housewrap is used underneath to guard the building envelope against water entry.

The function of all housewrap:

Housewrap also serves to minimize air flow through walls, though it is not a vapor retarder. In fact, housewrap is designed to stop liquid water while allowing water vapor to pass through. This lets moist or humid air escape from the interior and simultaneously keeps water outside.

Major types of housewrap

• asphalt-impregnated paper or fiberglass (the original material, still widely used, also known as Asphalt Saturated Felt)

• micro-perforated, cross-lapped films

• films laminated to spunbond nonwovens

• films laminated or coated to polypropylene wovens

• supercalendered, wetlaid polyethylene fibril nonwoven

• drainable housewraps

Puyoung Housewrap

Our housewrap is made from micro-perforated, coated to polypropylene or polyethylene woven materials.

Advantages of Housewrap

While housewrap is used in many areas, it is most beneficial in humid climates. This is because in areas that often experience heavy rainfall, there is a greater chance of water penetration damaging the framing of the house. Housewrap prevents damage from water penetration.

Generally higher levels of moisture content in the air are also common to wet climates. Housewrap allows moisture to escape from interiors, helping to ensure that wet conditions will not create problems such as mold growth.

Since housewrap helps prevent air movement through wall cavities, it also has some insulating value.

How to install correctly:

Housewrap should be installed before windows and doors are installed.

Upper layers should be lapped over lower layers.

Horizontal joints should be lapped at least 6 inches, and vertical joints should be lapped 6 to 12 inches, depending on the potential for wind-driven rain.

Staples or roofing nails a minimum of 1 inch long should be used and spaced 12 to 18 inches on-center throughout.

Proper joints should be covered with tape designed specifically for use with housewrap.

Size

Most popular size is 9ft x 150 ft or 9ft x 100ft. 3ft x100ft is also available in the market.

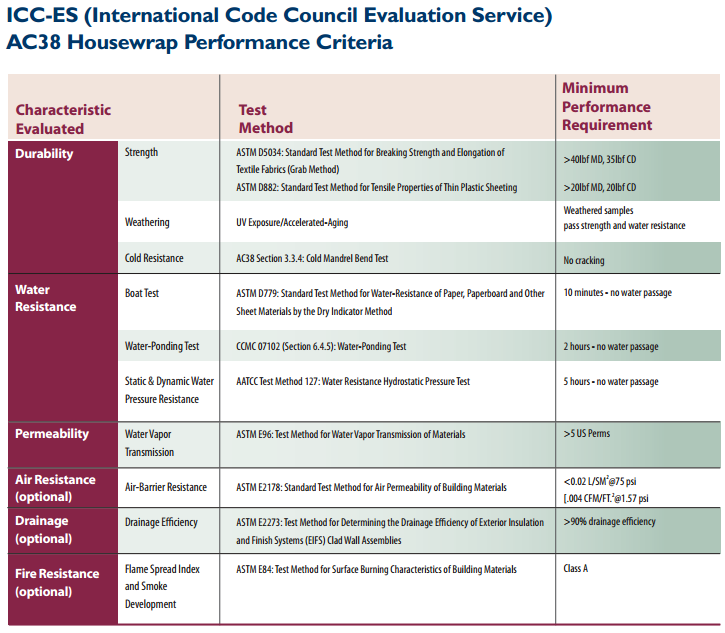

STANDARDS